Grinding is using a rotating abrasive wheel or tools to remove material, create a flat surface or cave surface. It is the high precision manufacturing way to make Metal Machined Products. The tolerances are normally achieved with grinding are ± 2 × 10−4 inches for grinding a flat material, and ± 3 × 10−4 inches for a parallel surface (in metric units: 5 μm for flat material and 8 μm for parallel surface. Grinding is also divided into surface grinding, inside diameter grinding and outside diameter grinding. In a words, it can not make excellent Machining Components without good grinding machine and excellent grinding technician. In Realhao Precision, the trained technician in our team can help you to make high precision machined parts.

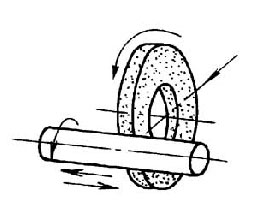

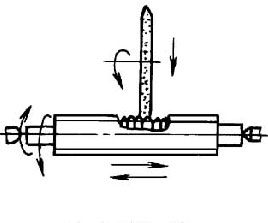

- (a) cylindrical grinding

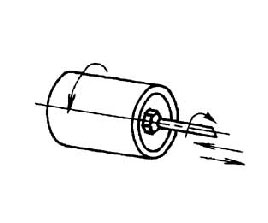

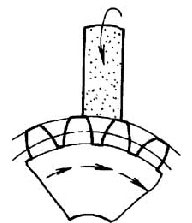

- (b) grinding the hole

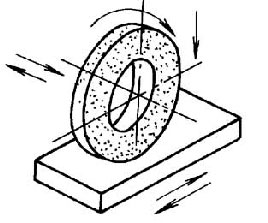

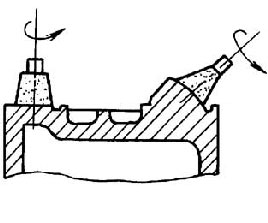

- (c) ground plane

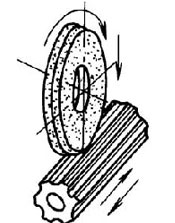

- (d) mill spline

- ((e) grinding thread

- (f) grinding teeth

- (g) grinding the rail

Facilities in Realhao

1 off x Grinding machines DXT850, Spindle: 12000rpm, Travel x,y: 800 x 500 mm Table size: 1000 x 700 mm

1 off x Grinding machines DXT850, Spindle: 12000rpm, Travel x,y: 800 x 500 mm Table size: 1000 x 700 mm

1 off x Grinding machines DXT850, Spindle: 12000rpm, Travel x,y: 800 x 500 mm Table size: 1000 x 700 mm

1 off x Grinding machines DXT850, Spindle: 12000rpm, Travel x,y: 800 x 500 mm Table size: 1000 x 700 mm